CO2 Laser Marking Machine

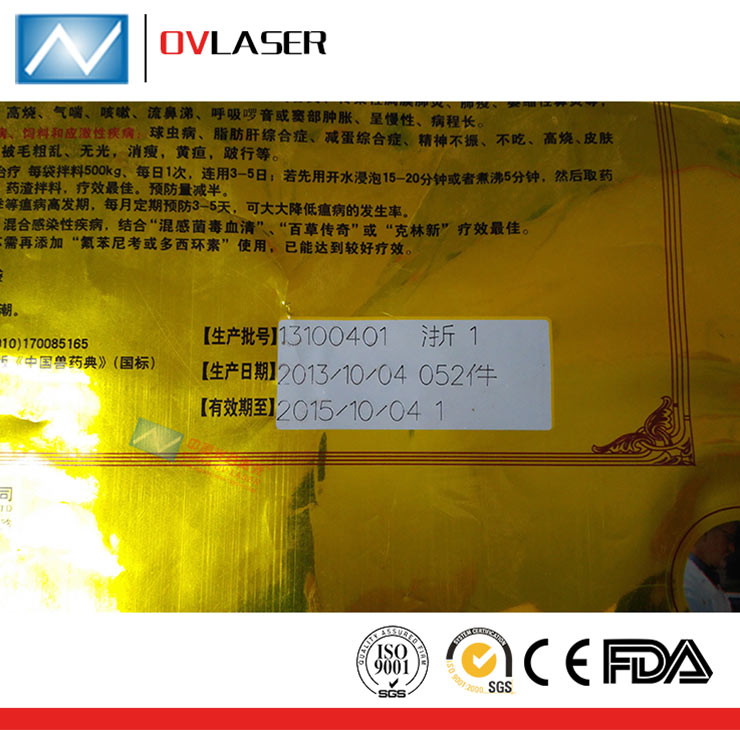

The CO2 laser marking machine uses a laser beam to mark permanent on the surfaces of a variety of different materials.

What on the surface evaporate and then what in the deep expose,which forms the permanent mark covers exquisite patterns, trademarks, dates, logos or characters.At present, CO2 laser marking machines are mainly used in some occasions requiring more precise and higher precision.

CO2 laser marking machines are widely used in food, medicine, wine, electronic components, integrated circuits (IC), electrical appliances, mobile communications, building materials, PVC pipe and other industries

CO2 laser marking machine have advantages in working without consumables and with permanence of marking

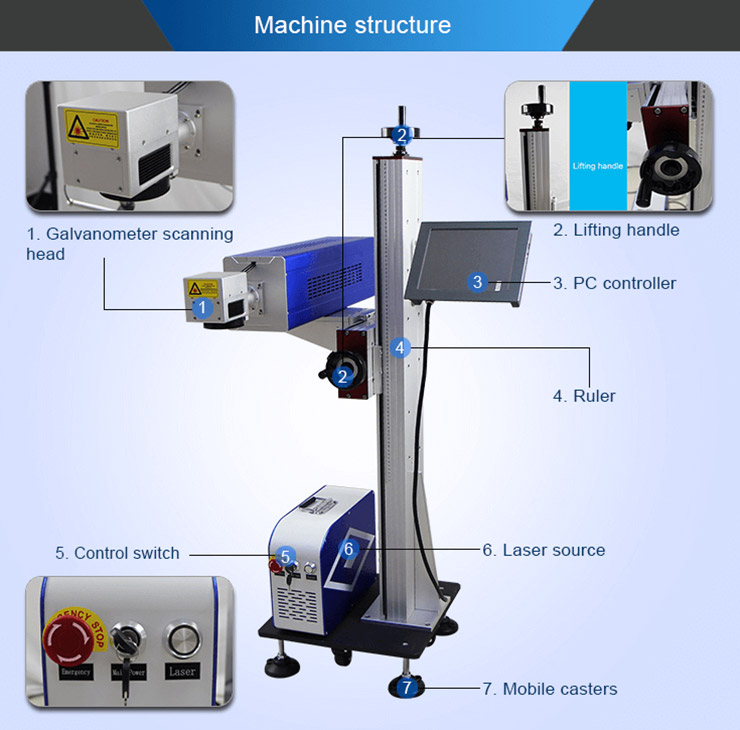

CO2 laser marking machine is mainly made of metallic packaging RF CO2 laser、high speed scanning galvanometer、Beam expander focusing system、red positioning system、industrial control cabinet、laser power supply、dedicated control software and computer.

The main features of CO2 laser technology

CO2 laser marking machine has faster speed, small whole compact machine structure and of easy installation,maintenance-free compared to traditional ink coding and coding machine.

It can use single or work with electric detector switch, encoder,flow process line workbench ,online dynamic flight line operation with prime printing effect

and marking speed can match modern mass production's high efficiency, high speed, high reliability and stability.

It is of excellent anti-counterfeiting function and enhance the brand image greatly.

It can mark permanently,clearly and it is clean, environmentally friendly, without polluting,low consumption,cost little to maintain.

The whole machine performance is extremely stable, high reliability, fully automatic 24-hour continuous real-time high-speed operation

Professional mark control software is a software system based on vector graphic marking.

It is suitable for BMP、AI、GIF、JPGE、PCX、TGA、TIFF、PLT、CDR、 DMG、DXF.

The system is flexible and fast, and the menu-friendly working interface is powerful, easy to operate, easy to master, and can be used for remote and close-range online marking control to realize real-time network software operation.

According to the model, it is mainly divided into: cabinet type, split type, flying type (online or assembly line), desktop type, large enclosed type, small enclosed type, electric door type and various non-standard forms

The function division according to the model is mainly as follows: the marking surface is flat (the workpiece plane, the curved surface with a small curvature)

Rotary type: The workpiece is a cylinder type, and the round enamel is marked in the circumferential direction (360 degree direction) (either the circumferential surface or the flat surface).

3D working type: 3D solid surface marking function, focusing spot is fine in the range of 1~60mm (drop) height, can realize laser marking on curved surface (spherical) workpiece more accurately, no defocusing during processing, through 3D dynamic laser Mark control hardware, software, configuration dedicated three-dimensional galvanometer, perfect control laser beam marking on any three-dimensional surface. The market is small and non-primary.

Working principle

The metal-packaged RF CO2 laser is a gas laser with a wavelength of 10.64um in the far-infrared band. The CO2 gas is used to charge the discharge tube as a medium for generating laser light. When a high voltage is applied to the electrode, a glow discharge is generated in the discharge tube. The gas molecules release the laser and amplify the laser energy to form a laser beam that is processed into the material. Therefore, the clear and beautiful logo is marked on the workpiece, which is all done under computer control.

Main advantages

1. The latest marking software ZGGLASER 8.0 uses WINDOWS interface, powerful and compatible. It can directly retrieve DWG and DXF format graphics from AutoCAD2000. There are spare interfaces in the extended function, which can be used with some pipeline operations. With data communication save network printing function, not only can save the marking content in the database, but also can recall the data in other databases.

2. Marking the workpiece does not require clamping positioning, loading and unloading is very convenient

3. There is no requirement for the hardness of metal parts, high and low can be marked, no pollution to the material and no deformation

4. There is no noise when marking work, the print content can be saved and saved, and the serial number printing can be automatically performed.

5. The technology is very mature, reliable performance, high repeatability, high positioning accuracy, long working time, fast marking speed, and the mark is very beautiful, the resolution is extremely high. The machine is small in size, long in life, reliable in performance, simple in installation and low in operating cost.

6. Compared with other laser marking machines, CO2 lasers have high efficiency, better beam quality, finer marking effect, perfection, and no need to replace parts frequently. There is no consumables. The life of CO2 laser can be up to 30,000 hours. Above, no maintenance is required during use

Applications: Non-metallic material marking, especially suitable for online automation.

Applicable to all non-metallic materials: coding, punching, laser tearing, stripping, stripping, fine micromachining, anodizing, oxygen-permeable conductive surface treatment, etc.

1. Instrumentation, automotive electronics, control panel, household appliances, electrical accessories, product packaging, stationery, brand display panels, wood products, label signs, cosmetics, pharmaceutical packaging, food, beverages, colored paper, various spray paint products, cigarettes , alcohol, handicrafts, etc.;

2. electronic components, capacitors, inductors, circuit boards, integrated circuits, keyboards, instrumentation, control panels, measuring tools, medical equipment, aviation parts, etc.;

3. gold, jewelry and, building materials, sanitary ware and so on.

|  |

Previous: Fiber Laser Marking Machine

Previous: Fiber Laser Marking Machine