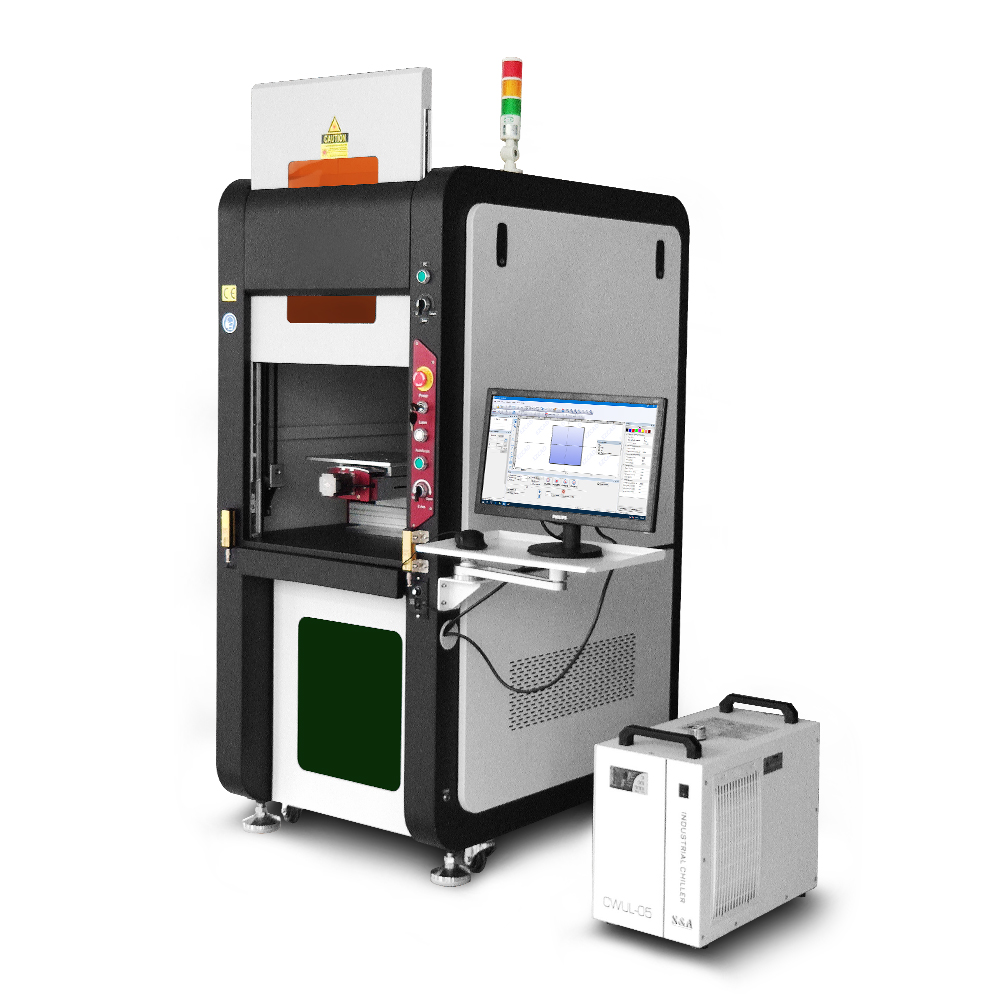

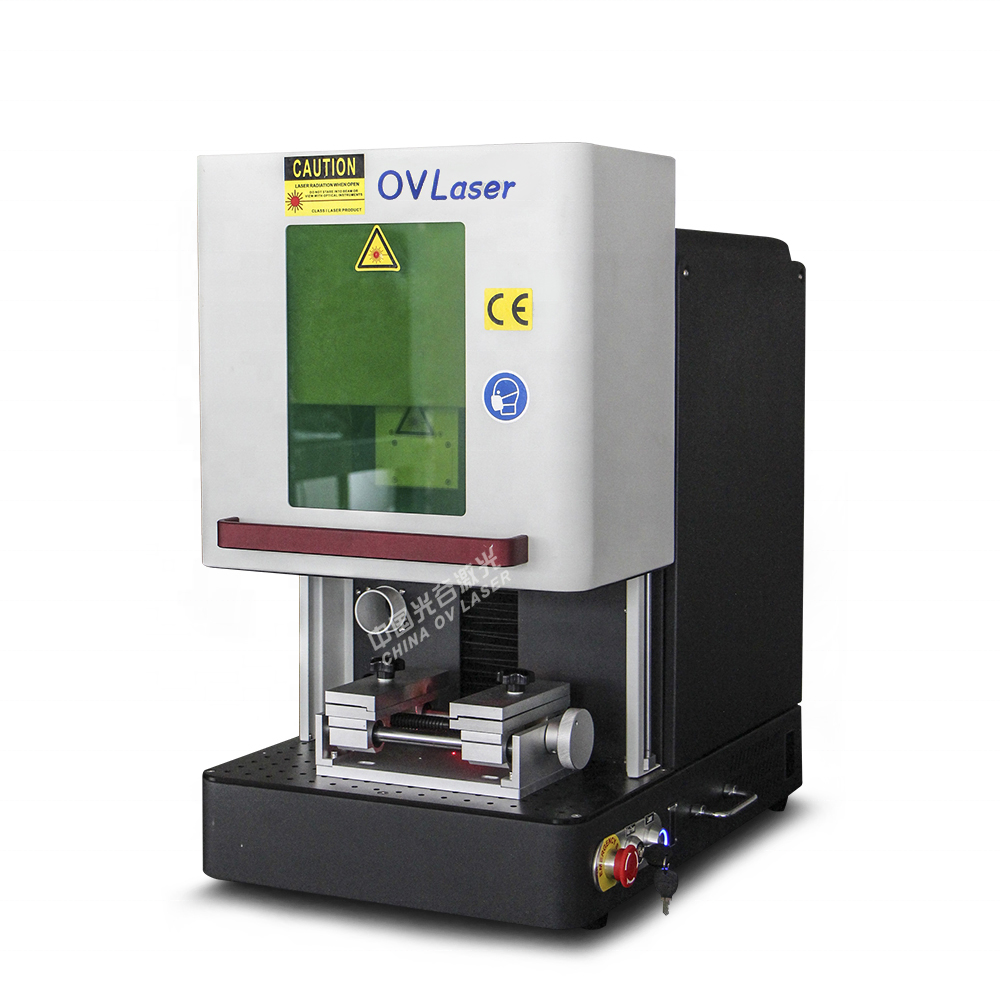

Laser Welding Machine Solution

Laser welding in stainless steel industry

Stainless steel is a very common type in our daily life. With the continuous expansion of China's stainless steel market, the consumption of stainless steel plates has increased year by year. Thin-walled stainless steel plates have also penetrated into various manufacturing fields, so thin-walled stainless steel plates Welding has become an important process in manufacturing, but the welding process characteristics of thin-walled stainless steel plates determine the difficulty of welding. The best stainless steel sheet is laser welding 0.1MM can be welded, the laser spot size can be adjusted arbitrarily, it can be well controlled. The deformation ratio is also not present. Therefore, the laser welding machine is undoubtedly the best choice for solving the welding of stainless steel sheets.

Stainless steel laser welding machine material selection precautions

(1) If the base metal is the same, the primary criterion is "matching with the parent metal". For example, if welding 310 or 316 stainless steel, the corresponding welding consumables are selected.

(2) Welding of dissimilar materials follows the criteria for selecting a base material with a high content of alloying elements. For example, for welding 304 and 316 stainless steel, 316 type welding consumables are selected.

(3) Many of the special cases exist that do not follow the principle of "matching the parent metal". At this time, it is necessary to "check the welding material selection table". For example, Type 304 stainless steel is the most common base material, but there is no Type 304 electrode.

Stainless steel laser welding machine features

1. High output power, stable energy, good beam mode and simple operation.

2. The laser power feedback control system ensures the stability of the laser energy output.

3. the use of British imported ceramic concentrating cavity, corrosion resistance, high temperature resistance, long service life.

According to statistics, since 2010, China has become the protagonist of stainless steel. By 2016, China's stainless steel output reached 24.94 million tons, accounting for 55.5% of the world's total output. In recent years, China's GDP has grown rapidly, and industries closely related to stainless steel consumption, such as construction, automobiles, household appliances, and daily-use stainless steel hardware products, have developed well, which has driven China's stainless steel consumption to continue to rise.

Stainless steel laser welding machine application selection

Stainless steel laser welding machine is widely used in battery industry, IT industry, electronics, optical communication industry, sensor industry, hardware industry, auto parts industry, mold maintenance welder industry, jewelry industry, optical industry, solar energy industry, power industry, etc.

Previous: Laser Cutting Machine Solution

Previous: Laser Cutting Machine Solution