The advantages of laser welding equipments

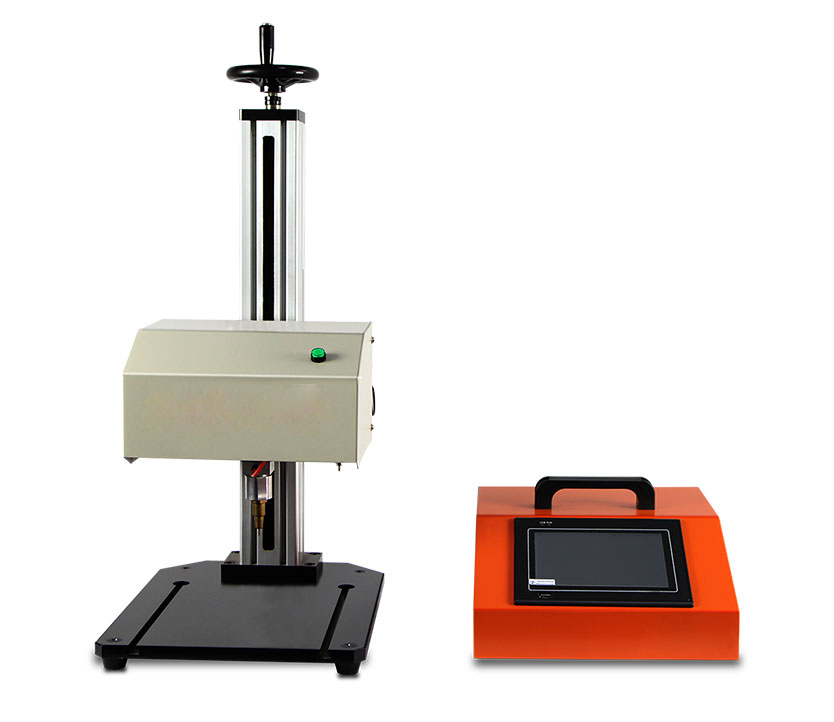

The hand-held laser welding machine is equipped with imported optical fiber, which is flexible and convenient. It can realize outdoor welding and the operation mode of the hand-held welding torch. It can weld the workpiece at any angle, and it is suitable for spot welding of various complex welds and various devices.

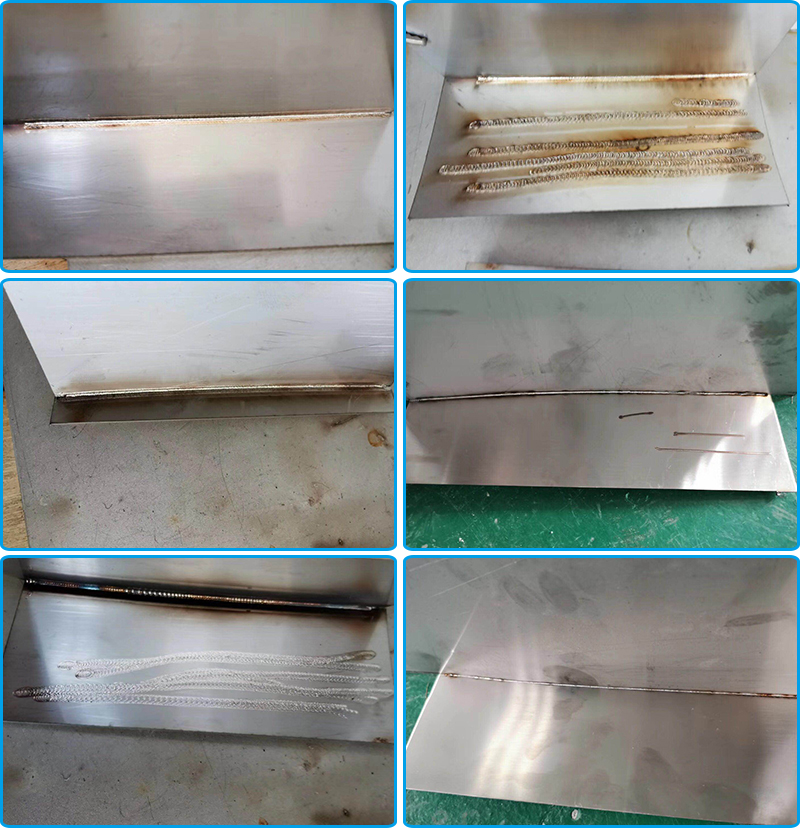

Handheld laser welding is 2 to 10 times faster than conventional welding when it works, and a machine can save at least 2 welders a year. The weld seam after welding is smooth and beautiful, reducing the subsequent grinding process, saving time and cost. The laser welding workpiece has no deformation, no welding, and the welding is firm. Laser welding consumes less material and has a long life.

Compared to the traditional arc welding, the hand-held laser welding machine solves the problems of large heat fusion, easy deformation, and post-processing when the metal sheet is welded. The operation is simple, and there is no need for the operation and use personnel.

The characteristic of handheld laser welding machine

The hand-held welding gun head is flexible and convenient for outdoor welding.

The operating mode of the hand-held welding tip allows the workpiece to be welded at any angle anywhere.

Intelligent switching of dual light paths, evenly distributing energy according to different time and different light.

It is suitable for all kinds of complicated welding methods and spot welding of various equipment.

The operation is simple, people know nothing about welding can get started to weld quickly,it is not necessary to hire professional welding workman to do the job.

No welding station is required, the space is small, the welding products are diversified, and the product shape is flexible.

Low material costs, low energy consumption and low maintenance costs.

Applicable materials:

It is mainly used for rapid welding of carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, pickling board, galvanized sheet, gold, silver, copper, iron, aluminum and other metal materials.

Industry application:

It can be used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal processing, etc. Manufacturing processing industry.

| Equipment type | GGHJ-S500W | GGHJ-S1000W | GGHJ-S1500W | GGHJ-S2000W |

| Output power | 500W | 1000W | 1500W | 2000W |

| Adjustment Power Range | 500W±2% | 1000W±2% | 1500W±2% | 2000W±2% |

| Laser Type | Continuous fiber laser | |||

| Laser wavelength | 1070nm | |||

| Frequency | 0~5Khz | |||

| Spot diamteter | 5~7mm | |||

| Welding Speed | 1~120mm/s | |||

| Welding accuracy | <=1mm | |||

| Welding line width | ≤4mm | ≤5mm | ||

| Welding thickness | ﹤1.2mm stainless steel ﹤0.8mm carbon steel | ﹤2.5mm stainless steel ﹤1.5mm carbon steel ﹤1mm aluminum | ﹤4mm stainless steel ﹤2.5mm carbon steel ﹤2mm aluminum | ﹤5mm stainless steel ﹤3.5mm carbon steel ﹤3mm aluminum |

| Beam quality parameter | M²﹤1.1 | M²﹤1.15 | M²﹤1.2 | M²﹤1.2 |

| Output fiber length | Standard 10m customizable extension | |||

| fiber bend radius | 100mm | |||

| Working mode | Continuous CW/ modulation | |||

| Operating environment temperature range | 15~35℃/<70% No condensation | |||

| Welding joint operation mode | Normal/hand-held swing welding mode | |||

| overall power consumption | 4KW | 6KW | 9KW | 12KW |

| Cooling Way | Built-in chiller | External water chiller | ||

| Power Supply | AC220V±10%/50Hz/40A | Triphase AC380V±10%/50Hz/40A | ||