Product Hightlights

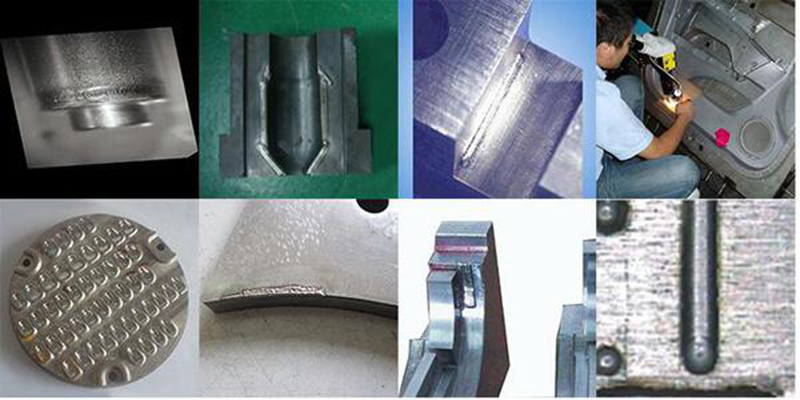

Boom Laser welding machine uses high-energy laser pulse on the processing of small areas of local heating materials, laser radiation through the heat transfer to the internal diffusion of materials, the material melts the formation of a specific pool to achieve the purpose of laser welding. The boom system equpped with laser welding machine is able to up and down, two-dimensional CNC platform, you can repair welding radius of 1.5 meters, the weight of several tons of large-scale mold, and the equipment is equipped with pulleys, easy to move, you can move directly to the injection molding machine Welding, no demolition die.It is also suitable for small and medium mold repair.

Specifications

Graphic Format Supported:ported:AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Application:Laser Marking

Condition:New

CNC or Not:Yes

Cooling Mode:Air Cooling

Control Software:EZCAD

Place of Origin:Hubei, China (Mainland)

Brand Name:OV Laser

Certification: CE, ISO, SGS, FDA

Warranty:3 years

Marking Area:200*200mm-1200*1200mm

Welding Deepth: ≤3.0mm

Applicable Material: metal

Power Supply:380VAC±5%/50Hz/63A

Pulse Frequency:1-50Hz

400W Mould Laser Welding Machine with Boom System , laser welding equipment

Supply Ability

100 Unit/Units per Month

Packaging & Delivery

There are 3 layers of package: waterproof thickening plastic bag; foam to protect from shaking; solid export wooden case.

Port

Wuhan port or any other China ports

Lead Time :

Quantity(Sets) 1-1 2-5 >5

Est. Time(days) 7 10 To be negotiated

Model | GGHJ-MD-400 |

Rated output power | 400W |

The polyoptical cavity reflector | Imported Ceramic Converging Cavity |

Laser Type | Nd:YAG Pulse xenon lamp |

Laser Wavelength | 1.064μm |

Max Pulse Energy | 90J/10ms |

Pulse width | 0.5ms-20ms |

Pulse Frequency | 1-50Hz |

Spot Adjustment Range | 0.2mm-2mm |

Welding Deepth | ≤3.0mm |

Observing system | Microscope (Optional CCD image amplification monitoring system) |

Boom Work Parameters | Three-axis induction infinitely variable speed, working radius1.5m |

X=100MM | |

Y=100MM(Dynamic rocker adjustment) | |

Z=4800mm 270°Swing welding | |

X,Y,Z Work Table | Bearing 200Kg , Panel 500*350mm (50*50mm-M6 location hole) |

Table Travel | X=200mm |

Y=100(manual control) | |

Z1=150mm(foot-plate electrical control) | |

Z2=150mm(manual control) | |

Maximum Power Consumption | 12KW |

Cooling System | Integrative forced cooling intelligent water tank |

Power Supply | 380VAC±5%/50Hz/63A |

Working Environment | Clean and dust-free/no source/13℃-28℃ Humidity 5%-75% |

Protective Gas | One Way(Argon) |

Welding Wire Diameter | 0.1mm~0.6mm |

Optional | anti-laser glasses/rotary fixture/CCD Monitor

|

Outline Dimension(L*W*H) | Main Frame:500×1200×1280mm Water Chiller:540×650×780mm(In kind prevail) |